Cable tray production line be used to produce cable tray . through exchange punching tooling to finish producing different specifications. One set of roller can make all specifications of cable tray. adjusting the width of roller to produce different width cable tray.

Product Description

Cable Tray Roll Forming Machine

1, Cable tray machine for producing all kinds of cable tray.

2,Completed cable tray production line working flow ,

Decoiler — leveling — feeding — punching — conveying table — roll forming — finished product

3,Equipment consists

The equipment consist with de-coiler , leveling machine, servo feeding

machine, the punching machine (with punching moulds ),automatic conveying table , main forming machine, cutting device, collection table .PLC control system

4,Main technical parameter of production line ,

material : GI steel sheet, low carbon steel.

the thickness of the steel sheet , 0.8-2.0mm

inner diameter of coil , Φ508mm

line speed, 4-6m/min ( adjustable)

5. The characteristic of the machine

5.1 Automatic de-coiler ,

type : cantilever drumming type

functional and structural features,

be used to support and expansion steel coiler , section steel welding fuselage. it is easy to operate.

technical parameters

material inner diameter : φ508mm

range of inner diameter : ф450-550

maximum outer diameter: φ1200mm

load capacity: ≤ 5T

5.2 Leveling machine :

type : nine rollers active leveling machine

functional and structural characteristics: leveling steel strip. Consist of pinch roller and leveling rollers, pinch rollers can be individually adjusted, upper leveling roller adopt overall structure, and establish two adjustment points on before and after, to form a certain angle, easy to improve the quality of leveling .

leveling roll is GCr15 high-frequency hardening, the hardness can reach HRC45-55.

technical parameters:

the number of leveling rollers: 9 rolls (up4/down5), 2 pinch rolls

motor power: 5.5KW

5.3 Correcting table

type : roller supporting , correcting

functions and Structure: correcting and with steel. Correcting device mainly consists of a pneumatic Prime bridge, roller, vertical roll-oriented composition. Guide wheels can be easily to adjust to different width. Galvanized rollers is beautiful and flexible.

5.4 Servo feeding machine

F type : servo feeding

F functions and Structure: Pinch and be with steel to the press machine. Polyurethane roller ensure that the feeding force. Feeding each error of feeding be controlled in rang of ± 0.15mm. Compared with the servo Clamp, feed length setting is more flexible, adapt to a wider range. This feeding device is more suitable for wide material , can effectively improve the feeding accuracy. Servo motor, measuring devices, digital control system are the imported components.

technical parameters:

maximum number of feeding: 30 ~ 40 times / min (adjustable)

feeding step: 100MM / step (adjustable).

5.5 Punching machine :

type : 21-200, 2000KN press machine ,friction clutch, PLC control, high productivity. has good rigidity of equipment, die has a long life.

function and structure: body adopt the whole steel welded structure, high stiffness, and reasonable structure, beautiful appearance. vertical crankshaft placement, fulcrum distance is short, crankshaft stiffness. gear be enclosed within the fuselage, speed motors, variable speed within a certain range, expanding the scope of the process. Adopt combined rigid chain of dry air friction clutch - brakes, the friction disc use high-tech products - semi-metallic friction materials, heat resistance, wear resistance reached a high level, the greater torque transfer , the driven inertia is small, easy installation and maintenance.

slider is a cast box structure, the slider overload protection device is installed to protect the sensitive and reliable, when the slide overload, the fuse voltage collapse destroyed, and send a signal, the slider is stopped, thereby protecting the machine tool and die from damage.

slider closed Height adopt motorized adjustment, digital display, the reading accuracy of 0.10 mm.

technical parameters:

the column spacing ≥ 960mm

nominal pressure: 2000KN

bominal stroke: 6mm

trips: 30 ~ 40rpm

motor power: 30KW

dimension: 2730x1640x3740mm

5.6 Punching mould

function and structure: 100MM / step, 40 steps / min to the beat of the Progressive complete punching and beading. mold use internal and external guiding structures; a large mold with separate small mold, punching, beading is be done step by step, can complete conversion between the slot (no pore pressure bars) and disc (punching beading).Both sides of the connection hole can be washed into through-hole and can knock down holes,

mold material: Cr12

5.7 cutting

type: PLC control cutting length without waste.

functions and Structure: fixed-length steel after punching. cutting device is on the end of the die feed direction, length is step.

cutting after punching , including cutting off mold.

5.8 Automatic conveying table

type: chain drive drum transfer machines.

function and structure: sheet be conveyed to roll forming machine after punching press and cutting. Consist of roller, motor reducer, welded steel frame and other components. both sides have adjustable guide panels, with the passive pressure wheel.

technical parameters:

transport material width: mm

maximum length of material : 8000mm

5.9 Feed conveyor frame

type: roll type (Adjustable)

function and structure: after correcting , punching , cutting , the sheet metal be conveyed smoothly into the roll forming machine. correcting device Mainly consist of level roller, guide stand wheel composition. Guide wheel can easily adjust to suit different widths of sheet metal.

5.10 Forming machine :

type: double cantilever gear drive, width adjustable universal forming machine and the overall mobile, fast (waist height and width) exchange specifications.

function and structure: sheet metal is rolled form by 20 stand rolls, gradually into finished cable tray. Consist of the speed AC motor, reducer, high-precision linear guides, left and right gear box, lateral adjustment mechanism, the roller group composition. A set of rollers to complete all the specifications of the cable tray, adjusting the position of roller frame to achieve replacement of specification .

technical parameters:

the number of horizontal roll stand: about 20

machine shaft: (specifically adjusted according to actual situation)

the level of roller distance: about 350-550mm

motor power: 22.5KW

line speed: 10-15m/min

5.11 Collection table

type: Finished cable tray arrive collection table, worker will collect products , non-powered roller.

function and structure: consist of section steel (square pipe), no power roller assembly, welding, play a role in supporting finished product ,can adapt 8-meter finished product.

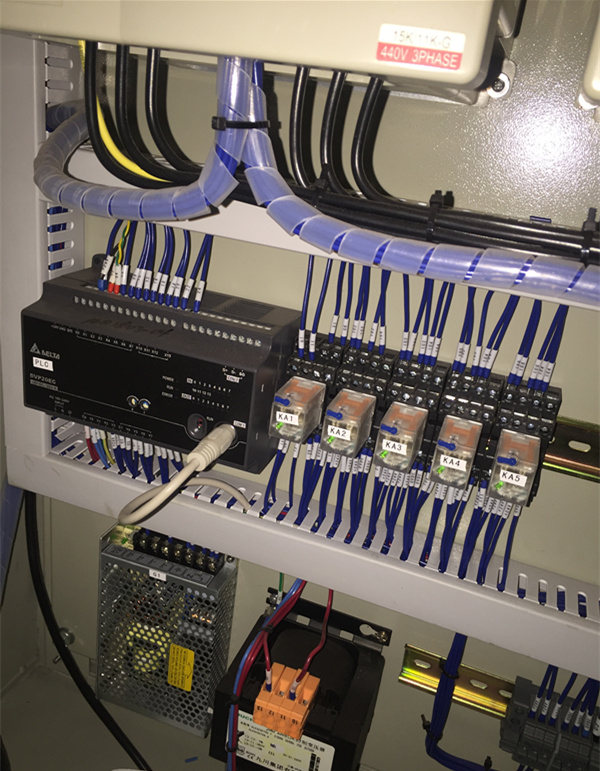

5.12 Electrical control system

the whole line adopt imported PLC control , touch screen be used for human-machine interface, achieving the interaction between man and PLC.

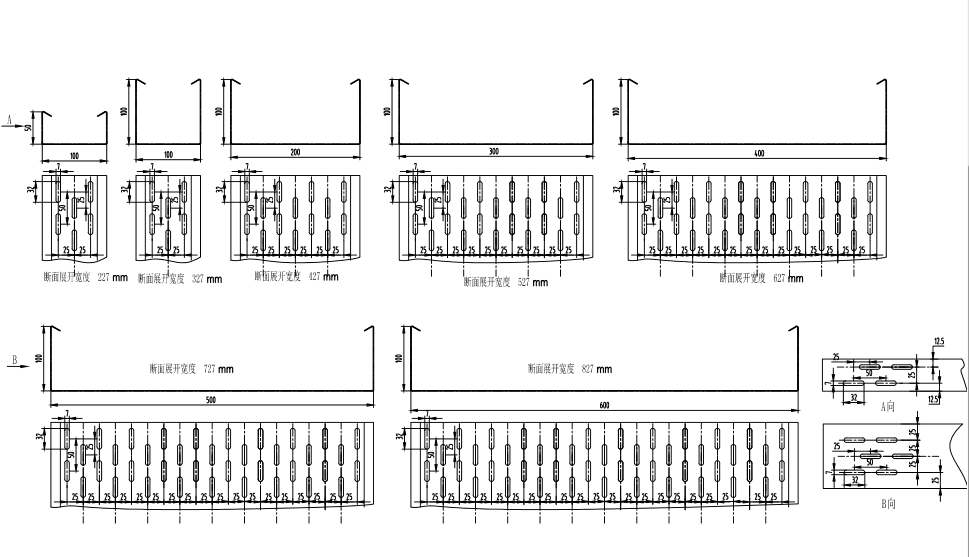

6, Cable tray with hole drawing

Product Features

Cable tay roll forming machine advantage

1, Cable tray production line for producing and adjust different width and height,cable tray width from 100-600mm, and height from 50-100mm.

2, PLC control system, automatically and easy handle.

3, Gcr15 roller with quench process, hardness reach HRC60-65 ℃.

4,Tracking cutting system with Cr12 Cutting blade.

Model and Meaning

Model, YX100-600

Cable tray machine is the equipment for production cable tray.

What is cable tray?

The cable tray is divided into a trough type & tray type & ladder type. Cable tray is composed of a bracket, a support arm and a mounting attachment. It can be erected independently, or it can be laid on various building (structure) and pipe rack brackets. It features simple structure, beautiful appearance, flexible configuration and convenient maintenance. All parts need to be galvanized and installed in buildings. If the bridge is outside the open sea or belongs to the corroded area, the material must have the characteristics of anti-corrosion, moisture resistance, good adhesion and high impact strength.

Technical Parameters

Cable tray forming machine technology detail

Item | Para | Memo | |

Suitable Material | Type | Hot rolled steel coil Galvanized steel coil | |

Thickness | 1.0mm -2.0 mm | ||

Yield Strength | 235-300MPa | ||

Coil Width (mm) | 227/327/427/527/627/727/827 | ||

Producing Speed | 5-10 m/min | Including punching time & cutting time | |

Motor power of leveling device | 5.5 KW | ||

Motor power of servo feeding device | 5.5 KW | ||

Motor power of 200 tons punching device | 18 KW | ||

Main motor power | 11KW*2 | ||

Hydraulic station power of Decoiler | 3KW | ||

Hydraulic station power | 7.5KW | ||

Power | AC380V,50Hz,3 Phase | customized | |

Dimension (L×W×H,mm) | About 30000×3600×2500 | ||

NAVIGATION

Tel: +86 755 2824 6186

Mob: +86 188 1435 5377

Fax: +86 755 2883 9980

E-mail: sales@superdamachine.com

Skype: live:demiwu2014

WhatsApp: +86 188 1435 5377