Struts Channel C Profile Roll Forming Machine For 4mm Thickness Metal Process.

Product Description

Precise, Fast, flexible Customized Shape C Roll Forming Machine Manufacture Line

Superda metal forming machines is automotive, very simple operation. Widely using in building, electrical industry, energy, home appliances, infrastructures, logistics sectors etc.

Metal shape as per client design.

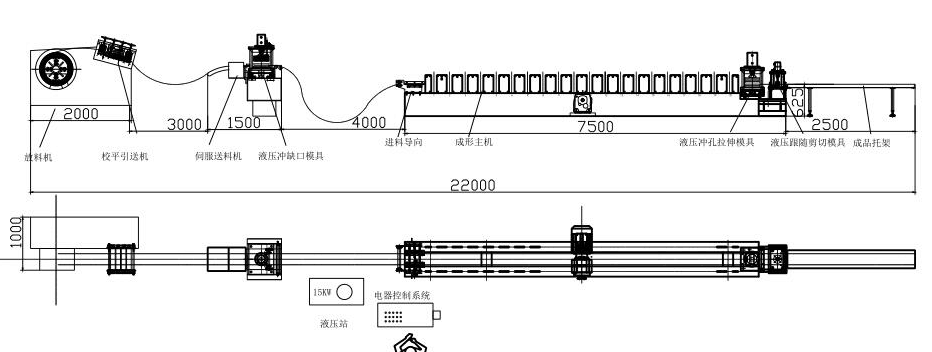

Metal roll forming machine production line process

Uncoiler straightener 2 in 1 → Guide device → Hole punch →roll forming machine →shear device (including knife)→ finished product rack

Layout as below

Machines List

2 in 1 Uncoiler straightener

1,Type Manual Expansion

2,Parameter

1)Passive discharge

2) Coil weight:< 2T

3)Coil inner D.:φ450mm-φ530mm

4)Max. Width.400mm

5) Thickness .2-4mm

6) Straightener roller :7 pcs

8) Power.1.5kw

Good quality straightener

Servo Feeder

3.1 Max. feeding width 400mm

3.2 Feeding thickess 2-4mm

3.3 Motor,1.3KW(Yaskawa)

Guide device

C Channel Production Line Main Forming machines

5.1 Forming Roller:20 stations,and add Rub-roll, To make sure the surface profile no scratches.

5.2 Side Panel:T.18mm ,A3 steel Heavy duty 。

5.3 Rolling speeding: 2-8 m/min。

5.4 Roller material:#45,overall quenching, hardness HRC56-62 ℃.

5.5 Motor power:18KW。

5.6 Main Roller :¢65mm,45 #。

5.7 Equipment base: 400# H type using welded steel plate.

5.8 Transmission: chain drive.

5.9 Security: across the board with emergency stop buttons, easy to handle emergencies, to ensure that equipment and operator safety. And other gear in the chain and the staff could easily lead to injury transmission section covered with protective cover, to ensure the safety of workers.

Flat collect rack

Electrical control system

The entire line imported PLC control, LCD touch screen, man-machine interface. People interact with the PLC. Operator setting the program to run automatically (programmable control) and control process monitoring, production line operator control and modify the control parameters, and real-time monitoring the equipment status & parameters and fault indication. Workpiece length digital setting, adjustable length can be adjustable as well. Real-time monitoring of equipment operating status and fault indication.

Operation manual / automatic two styles. With manual and automatic switching function: In the manual mode, can be stand-alone operation, easy maintenance; In automatic mode, carry out full production run, in order to start; across the board with emergency stop buttons, easy to handle emergencies, to ensure that equipment and operating personnel Safety.

Machinery main components of the brand:

PLC control system: Siemens

Inverter: Taiwan Shilin

Encoder: Omron

Touch screen: Siemens

Some components are Schneider brand devices.

Devices completed channel with hole line

| No. | Machine name | QTY | REMARK |

| 1 | Uncoiler straightener | 1 | |

| 2 | Servo Feeder | 1 | |

| 4 | Guide device | 1 | |

| 5 | Forming machine | 1 | |

| 7 | Follow Shear | 1 | Including knife |

| 8 | Collect rack | 1 | |

| 9 | Control system | 1 |

C Profile Roll forming machine accessories brand

| No. | Name | manufacturer |

| 1 | Motor & Reducer | Domestic brands |

| 2 | The main key bearing | Domestic brands |

| 3 | Inverter | Shilin |

| 4 | PLC Systems | Siemens |

| 5 | Low-voltage electrical | Schneider |

| 6 | Encoder | Omron |

| 7 | touch screen | Siemens |

| 8 | Hydraulic system | Domestic brands |

Technical Parameters

Manufacturer machine for production customized shapes C .

Technical parameters

| No. | ITEM | PARAMETER | REMARK | |

| 1 | MATERIAL | Type | Cold-rolled strip steel, galvanized sheet | |

| T.(mm) | 2-4mm | |||

| Yield Strength | G245MPa | |||

| 2 | Forming product Width | Depend on design | ||

| 3 | Forming speed (m/min) | 8-12m | ||

| 4 | Forming main power (KW) | 18.5 KW | FYR | |

| 5 | Hydraulic power (KW) | 5.5 KW | FYR | |

| 7 | Voltage | AC380V,50Hz,3P | Custimized | |

NAVIGATION

Tel: +86 755 2824 6186

Mob: +86 188 1435 5377

Fax: +86 755 2883 9980

E-mail: sales@superdamachine.com

Skype: live:demiwu2014

WhatsApp: +86 188 1435 5377