Floor deck roll forming machine for making metal floor deck. There are automatic floor deck color steel cold roll forming machine,galvanized steel floor decking machine,floor tile decking making machine

Product Description

Floor Deck Roll Forming Machine

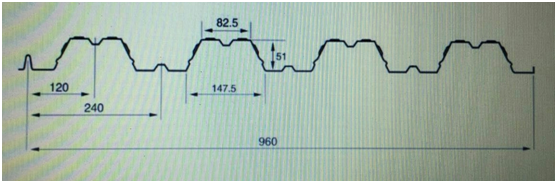

Item:YX51-240-960 Floor Deck Roll forming machine

Floor Deck Drawing:

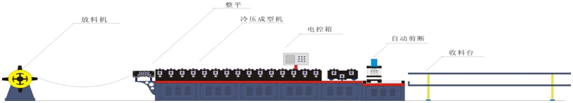

Floor deck production line process go through

Decoiler―――Guide device―――Roll forming machine――― Hydraulic Cut (Incuding Knife)―――Finished product rack

Device:Decoiler、Guide device、 Main Roll forming machine, Hydrualic shear, Finished product rack、PLC control box、Hydrualic station,ect.

Material:

Cold –strip steel、Galvanized Sheet

Product width:960mm;

Material strength:Q245-350Mpa

Material Width: 1300mm

Thickness: 1.0mm

Device:

1,Decoiler:1 pcs

Not power

Inner diameter:460-520 mm;Out diameter:Max.1200nmm

Loading:Max. 3T; Max. width. 1300mm;

2,Main Roll forming machine

Side panel thickness: 18mm A3 steel;

Roller material,#45;

Reel:¢95mm, 45# Steel;

Main Motor:15KW* pcs

Floor deck material Q195/Q235/Q345 Cold –strip steel、Galvanized Sheet

Total 32 pair rollers & Speed, 8-12 m/min

Floor deck machine photo just for reference

3, PLC Control Box:1 PC

Automatic Control Quantity and length

4. Hydraulic station and Shear

4.1 Function:Hydraulic shear (Mould 1 set)

4.2 Shear knife materil, Cr12,Hardness HRC56-58

4.3 Hydraulic system working pressure:16MPa

4.4 Hydraulic station:5.5KW( Hydraulic shear)-

5,Finished product rack:3 Pcs, not power

electrical control system

The entire line imported PLC control, LCD touch screen, man-machine interface. People interact with the PLC. Operator setting the program to run automatically (programmable control) and control process monitoring, production line operator control and modify the control parameters, and real-time monitoring the equipment status & parameters and fault indication. Workpiece length digital setting, adjustable length can be adjustable as well. Real-time monitoring of equipment operating status and fault indication.

Operation manual / automatic two styles. With manual and automatic switching function: In the manual mode, can be stand-alone operation, easy maintenance; In automatic mode, carry out full production run, in order to start; across the board with emergency stop buttons, easy to handle emergencies, to ensure that equipment and operating personnel Safety.

Floor deack roll forming machine main components of the brand:

PLC control system: Siemens

Inverter: Panasonic

Encoder: Omron

Touch screen: Siemens

Some components are Schneider brand devices.

Product Features

Guarantee of Quality

Superda guarantee floor deck roll forming line design accordance with clients required drawing, machine is brand new. Specification and performance as stipulated in drawing and operation with good smooth.

Terms of Payment

By TT, 30% in advance, 70% before delivery.

Time of Shipment

60 days after received deposit

Model and Meaning

Model: YX51-240-960

Floor deck roll forming machine for mass production construstion material foor deck.

Floor deck name as floor board, also known as profiled steel plate, steel plate, steel floor plate. It was first called the profiled steel plate, which is the collective name for all the steel plates pressed by the plate press.

The floor slab is made of galvanized steel sheet by roll forming, and its cross section is V-shaped, U-shaped, trapezoidal or similar. It is mainly used as a permanent template and can also be selected for other purposes.

The earliest profiled steel plates were mainly used for roof slabs on the factory floor, and later there were profiled steel plates for the floors, which were gradually classified as floor deck.

The equipment for producing floor deck machinery name as floor deck roll forming machine & floor deck sheet machine & steel floor deck roll forming line.

Technical Parameters

| No | Item | Parameter | Remark | |

| 1 | Suitable Material | Type | galvanized steel | |

| Width(mm) | Thickness(mm) | |||

| 240 | 0.8-1.5 | |||

| 960 | 0.8-1.5 | |||

| Yield Strength(Mpa) | 230-350MPa | |||

| 2 | Production Speed(m/min) | about 20 | depend on design | |

| 3 | Roller Stations | 20-36 | depend design | |

| 4 | Roller Material | 45 | with quench treatment | |

| 5 | Cutting Model | Hydraulic Cutting | ||

| 6 | Power source | Type | 380V/3PH/50HZ | custmizied |

| Total Power | About 38KW | depend on design | ||

| 7 | Dimension | 16000*1800*1500 | depend on design | |

NAVIGATION

Tel: +86 755 2824 6186

Mob: +86 188 1435 5377

Fax: +86 755 2883 9980

E-mail: sales@superdamachine.com

Skype: live:demiwu2014

WhatsApp: +86 188 1435 5377