Sep. 06, 2020

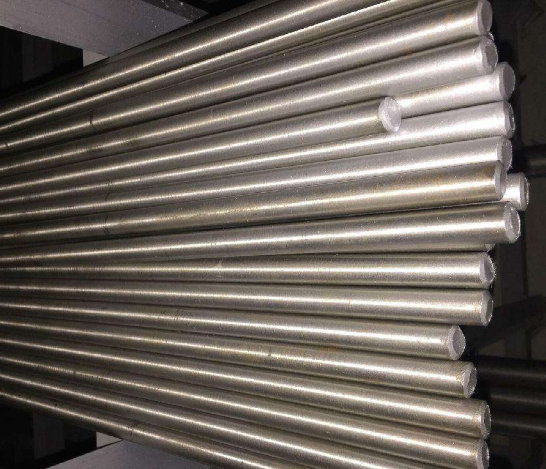

The concept of stainless steel forming and heat treatment process

Stainless Steel Process with the help of cold treatment, the metal is reinforced, which is achieved by tensile working the metal. The deformation results in a higher dislocation network density, which actually strengthens the metal.

Strain hardening process which working for hardening and cold working are the same concept. The deformation produced during cold working is always kept below the recrystallization temperature. Otherwise, the process will be called hot working instead of cold working.

Recrystallization point: Recrystallization is to control the evolutionary arrangement of non-hardened and uniform crystal grains formed at this temperature point. The proportions of the crystals in all directions are similar. Brittleness, reduced rigidity and hardness, but increased ductility.

Hot working process idea, In the hot working process, the metal will not undergo strain hardening, so strain hardening can only be achieved in the cold working process.

Annealing: Annealing is more specifically called a heat treatment process. In it, the metal is heated to a specified temperature to reduce the burden on the material, soften the material and change its performance. The hot annealing process increases ductility, while the cold working process reduces ductility.

The ductility and ductility of materials: ductility is a characteristic of metal, which can be plastically deformed or manipulated under the action of tensile force. On the other hand, ductility is a property of metals, and under these properties, metals will deform under compressive stress. In engineering, elasticity is the degree of non-permanent deformation of metal. In this inelastic deformation, if the applied stress is removed, the metal will return to its original form.

NAVIGATION

Tel: +86 755 2824 6186

Mob: +86 188 1435 5377

Fax: +86 755 2883 9980

E-mail: sales@superdamachine.com

Skype: live:demiwu2014

WhatsApp: +86 188 1435 5377