Drawer slide rail making machine including drawer slide roll forming machine, bead rack punch machine, slide rail assembly machine

Product Description

Drawer slide rail making machine China manufacturer

How to making a completed set drawer slide rail?

Ⅰ, Drawer slide roll forming machine

There are 3 sets roll forming machine for making drawer slide.

Outside rail roll forming machine

Middle rail roll forming machine

Inner rail roll forming machine

Technical Parameters | |||

Model | SP-4512 | ||

Product Name | Slide rail roll forming machine | ||

| Function | Forming drawer slide profiles | ||

| Drive | Chain | ||

Roller Seat | A3 steel | ||

Roller stations | Outrail roll forming 16 station, middle and inner rail 14 stations. | ||

Forming roller | #45, CNC machining after heat treatment | ||

Motor power of forming machine | 7.5 kw | ||

Line speed | 8--13m/min | ||

Thickness of material | 0.8--1.4mm | ||

Motor power of hydraulic station | 7.5kw | ||

| PLC/Touch screen | Panasonic | ||

2,Bead rack (ball case) punch machine 18T

Punch machine for producing beack rack metal parts for slide rail 10-24 inch bead frame.

This set including simple uncoiler and feeder.

Bead rack photo as below show

3, Bead press machine

Assembling bead into plastic strip, high efficiency and easy handle

4, Full-automatic assembly machine

include the machine of automatic put the fish-shape plastic to the rail

Component structure:

Eectric appliance, PLC (Mitsubishi 60Z) 2 sets

40Z 2 setstouch screen(Kinco)4sets

Servo motor (1000W 1set, 400W 1set)

Stepper motor (110 stepper motor 1set, 86 stepper motor 2sets)

Gear reducer motor (total 7 sets)

Frequency changer (Schering 2sets)

Vibration disk (4sets).

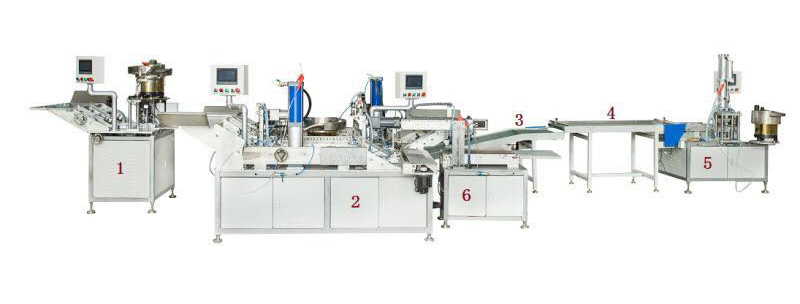

Drawer slide full-automatic assembly machine

1,inner rail automatic riveting machine

2,assembly main machine

3,slope conveyor

4.plane conveyor belt

5.outside rail bending machine

6.clamp bead stip manipulator

Total net weight: 1580KG,

Size, L9.5m x W3.5m x H1.5m

Voltage 220V,

Frequency 50 to 60HZ,

working efficiency 32 pcs/min, Power 2.8KW

Automatic drawer slide assembly machine in workshop

Product Features

Slide rail making machine for making drawer/cabinet rail.

1, High technology, simple operation, durable forming line

2,Ajustable length setting.

3, PLC Constrol system

The whole line technological process: material rack----main engine----cutting off---- collecting material

The main forming frame is use 100mm*80mm*3mm rectangular tube, T. 25mm A3 carbon steel plate full welding, and process by milling machine table of the gantry milling machine.

The forming wall panel adopt 40mm thickness panel.

Model and Meaning

SP-4512

Slide rail making machine for making telescopic channel

Slide rails, also name as guide rails and telescopic channel, are fixed on the cabinet of the furniture, and the drawers or cabinet panels of the furniture are connected to the movable hardware connecting parts. The slide rails are suitable for the drawer connection of furniture such as cabinets, bathroom cabinet, furniture, briefcases and other wooden and steel drawers.

Technical Parameters

Slide rail making machine

PLC control forming line and automatic assembly line

| Description | 45mm slide rail |

| Item No. | SP-4512 |

| Material | Stainless steel, cold rolled steel |

| Finish process | Zinc Plated, Electroplating Black |

| Thickness | 0.8-1.2mm |

| Application | Kitchen cabinet, drawer, desk |

| Type | 3 fold slide rail |

NAVIGATION

Tel: +86 755 2824 6186

Mob: +86 188 1435 5377

Fax: +86 755 2883 9980

E-mail: sales@superdamachine.com

Skype: live:demiwu2014

WhatsApp: +86 188 1435 5377